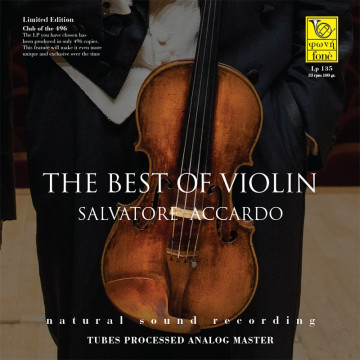

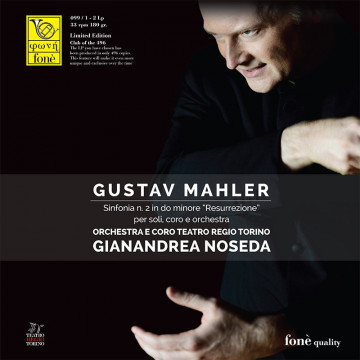

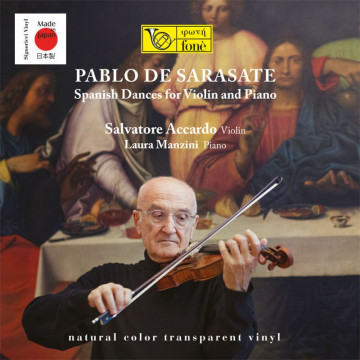

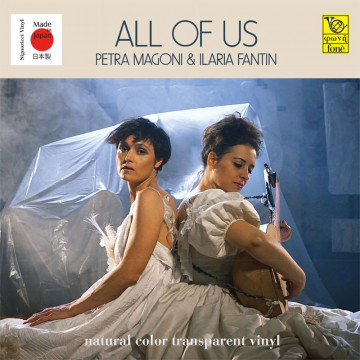

Following pressing requests from the enthusiast market, and after a long series of tests to determine the best support material to use, fonè is now able to make available our best titles in LP form, using 180/200 gram virgin vinyl as the base.

This is strongly contrary to the current of present-day international market trends, which tend ever more towards a homogenised product with little real content. These are pressings of the highest quality and are dedicated to those who can appreciate the search for perfection in the field of sound reproduction, to collectors, and to connoisseurs of beautiful things.

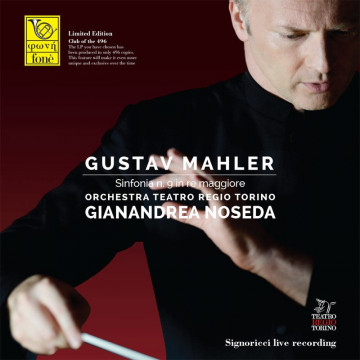

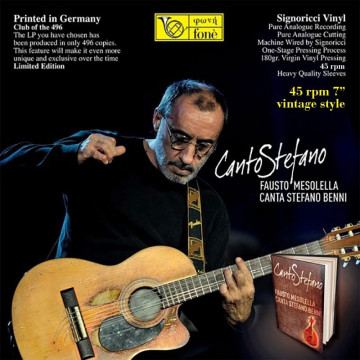

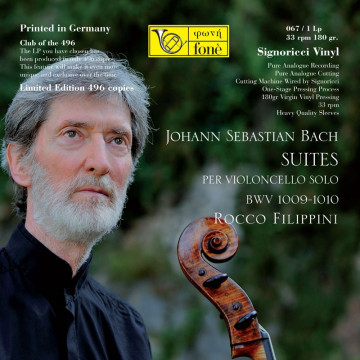

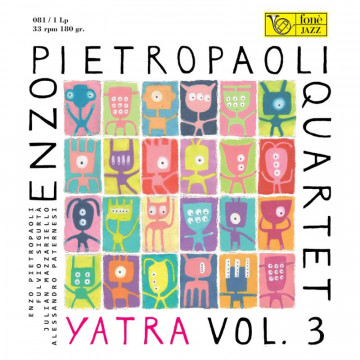

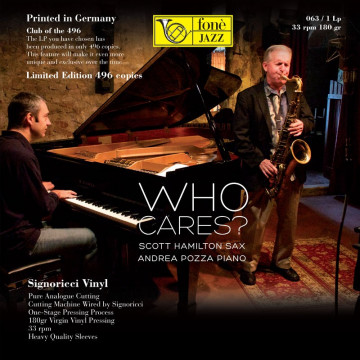

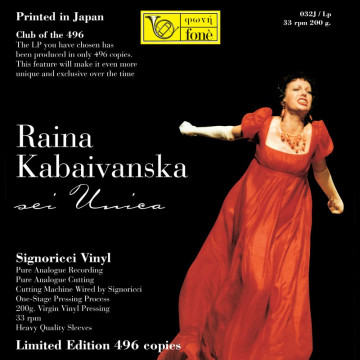

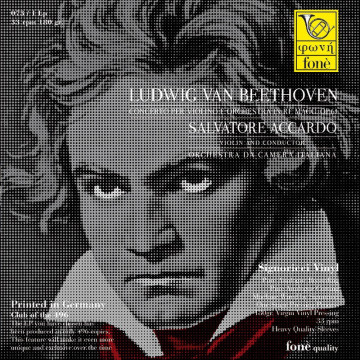

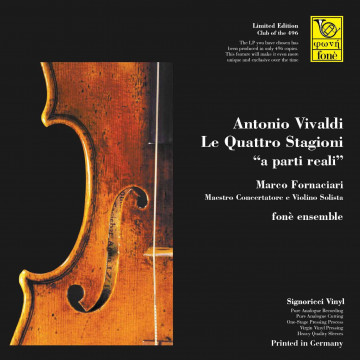

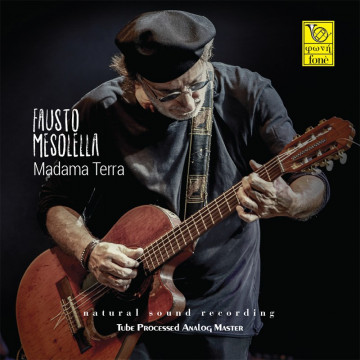

Signoricci Vinyl

giulio cesare ricci “Signoricci” started collecting vinyls and tape recorders when he was 10 years old. While most youngsters dream of becoming engine drivers, police officers or fire fighters, giulio cesare ricci was different, at the age of 18 he did his first cutting. All that he wanted to do was to own his own record company, and 40 years ago the dream came true when he launched fonè with the first vinyl release and since then the production of LPs has been central to his activity with professional collaborations at the highest levels in the analogue domain.

Now the Signoricci ultimate vinyl generation pressed in Germany and Japan from analogue master and with analogue cutting is a reality.

A step of the production process fundamental to guarantee the transfer and the preservation of the originary quality of the Analogue Master is represented by the Cutting which is done with State of the Art machines, with extreme dedication, and in continuous evolution. This is not only important to get a superlative control-quality on the pressing process of his LPs, but also to obtain the highest possible quality.

Like a fine-art photography printing, like a unique bottle of wine, Signoricci Vinyls are made with the highest knowledge, technique and extreme care, each detail is taken into account and the manual component characterizes every step of the production process.

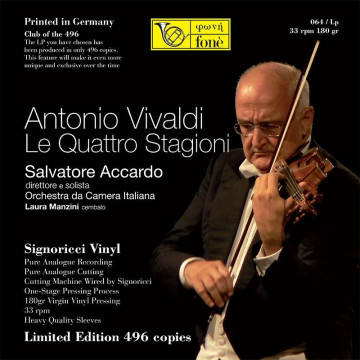

Signoricci vinyls features:

- Limited Edition 496 pcs, each edition is different. The laquer is processed with one galvanic only and after 496pcs the stamper is destroyed on purpose, for additional quantity another cutting session is necessary

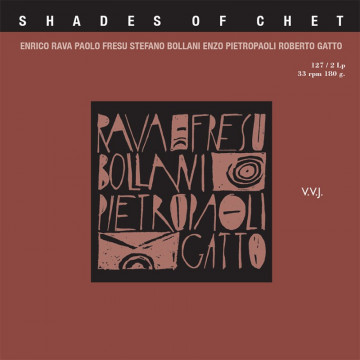

- Different formats: 4 LPs one sided for enhanced disc quality and minimized pressing stress, 2 LPs one sided, 2 LPs double sided, 1LP double sided

- Pure Analogue Recording, Master Ampex ATR-100 Modified by David Manley, 76 cm/sec, 2 tracks ½ inch

- Pure Analogue Cutting, cutting of the laquers has been made with the support of analogue delay - no digital device is used for this operation

- One stage pressing process, instead of the three usual steps the stamper is directly made from the laquer

- 200 grams / 180 grams virgin vinyl pressing

- Extra long 24 hours cooling time

- 45 Rpm, 10-13 min per side maximum groove width (110 micron) /depth and optimized space between the grooves

- 33 Rpm, 18-20 min per side maximum groove width (110 micron) /depth and optimized space between the grooves

- Heavy quality sleeves

- Made in Japan - uniquely 200g. productions with 100% virgin vinyl

- Made in Germany - 180g. productions with 100% virgin vinyl

![Musica nuda - Verso sud [LP]](https://foneshop.it/485-home_default/musica-nuda-verso-sud-lp-.jpg)